|

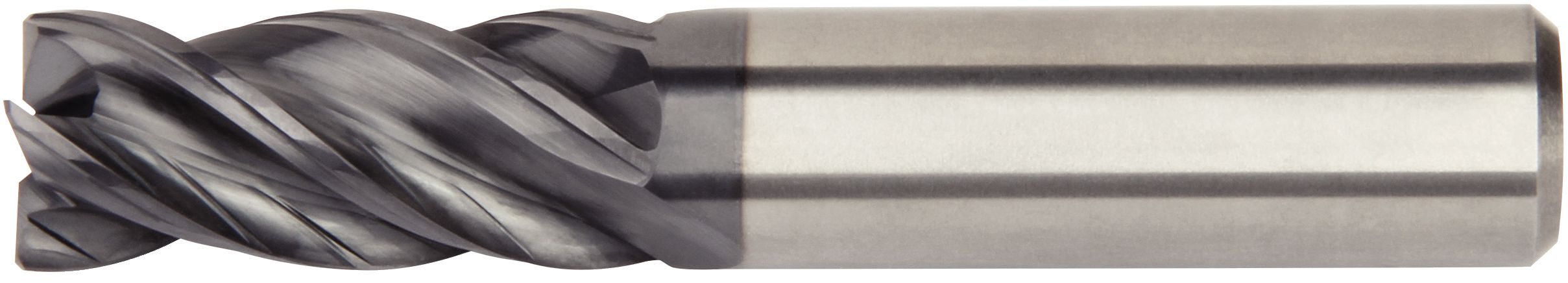

HARVI I TE |

HARVI I TE - Maximum metal removal. Maximum productivity. Maximum benefit.

For steel, stainless steel, cast iron, and high-temp alloys.

Buy 3/8" endmill at promo price of $41.00

Buy 1/2" endmill at promo price of $56.00

HARVI I TE - Inch - Corner Radius

|

|

| Price | Sku | Name | Adapter Style | Flutes | D1 | D | Ap1 max | L | Rε |

| $41.00 | KEN 6827274 | H1TE4RA0375R100HAR015 KCSM15 | Straight-Cylindrical | 4 | 3/8 | 3/8 | 1 | 3 | 0.015 |

| $56.00 | KEN 6827273 | H1TE4RA0500R125HAR015 KCSM15 | Straight-Cylindrical | 4 | 1/2 | 1/2 | 1 1/4 | 3 1/4 | 0.015 |

| Recommended feed per tooth (IPT = inch/th) for side milling. For slotting, reduce IPT by 20%. | ||||||||||

| KCSM15 | D1 — Diameter | |||||||||

| Side Milling | Slotting | Cutting Speed — vc SFM | frac. | 3/8 | 1/2 | |||||

| Material Group | ap | ae | ap | min | max | dec. | 0.375 | 0.500 | ||

| P | 0 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | – | 660 | IPT | 0.0030 | 0.0037 |

| 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | – | 660 | IPT | 0.0030 | 0.0037 | |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 460 | – | 620 | IPT | 0.0030 | 0.0037 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 390 | – | 520 | IPT | 0.0025 | 0.0032 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | – | 490 | IPT | 0.0022 | 0.0028 | |

| 5 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | – | 330 | IPT | 0.0020 | 0.0025 | |

| 6 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | – | 250 | IPT | 0.0017 | 0.0021 | |

| M | 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | – | 380 | IPT | 0.0025 | 0.0032 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | – | 260 | IPT | 0.0020 | 0.0025 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 200 | – | 230 | IPT | 0.0017 | 0.0021 | |

| K | 1 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 390 | – | 490 | IPT | 0.0030 | 0.0037 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 360 | – | 460 | IPT | 0.0025 | 0.0032 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 360 | – | 430 | IPT | 0.0020 | 0.0025 | |

| S | 1 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | – | 300 | IPT | 0.0025 | 0.0032 |

| 2 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | – | 260 | IPT | 0.0020 | 0.0025 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 0.5 x D1 | 80 | – | 130 | IPT | 0.0013 | 0.0017 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | – | 200 | IPT | 0.0019 | 0.0023 | |

| H | 1 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 260 | – | 460 | IPT | 0.0022 | 0.0028 |

| 2 | 1.5 x D1 | 0.2 x D1 | 1.0 x D1 | 230 | – | 390 | IPT | 0.0017 | 0.0021 | |